Storage of Material

Storage of timber material is a combination of raw, pre-formed and laminated timber. The pre-formed timber consists of everything we need for our windows and …

Learn More

Cutting To Desired Length

Our cross-laminated timber is taken from storage, and our technicians begin by programming the chop saw machine to cut the desired length required.

See Video

Planer Process for Windows

Once the timber is cut to the desired length, it enters the sanding process, which serves two purposes. One is to remove rough edges or imperfections, and the …

See Video

UC11 Machine

The UC11 machine, otherwise known as a profiling machine, performs multiple tasks and is an important part of our window and door process. It profiles external …

See Video

Grooves (CNC Machine)

After the timber for windows and doors has been profiled, we use a CNC (Computer Numerical Control) machine specifically designed for precision cutting and …

See Video

Making The Frame for Windows

The timber pieces are placed into a press machine, which is specifically designed for assembling and glueing window frames and sashes. The press applies …

See Video

Glazing Bars to Window Sashes

Once the timber sashes have been fully formed, integral external glazing bars, otherwise referred to as ‘astragal bars’, are profiled, glued and pinned to hold …

Learn More

Priming & Caulking

Once the frames for window and door frames are pressed together, they are then prepped for the paint process. All of the internal and external joints are primed …

See Video

Priming Spray Shop

When the window and door frames reach the first stage of the spray shop, they are ready for full priming. The primer we use is a water-based, breathable system …

Learn More

Sanding Down Primer

Following the application of each primer coat, we meticulously sand the surface to achieve a smooth finish, eliminating any imperfections, rough patches, or …

Learn More

Top Coat Spray Shop

After priming and sanding, the window and door frames are sent to the spray shop, where they undergo a meticulous painting process, which involves three coats …

See Video

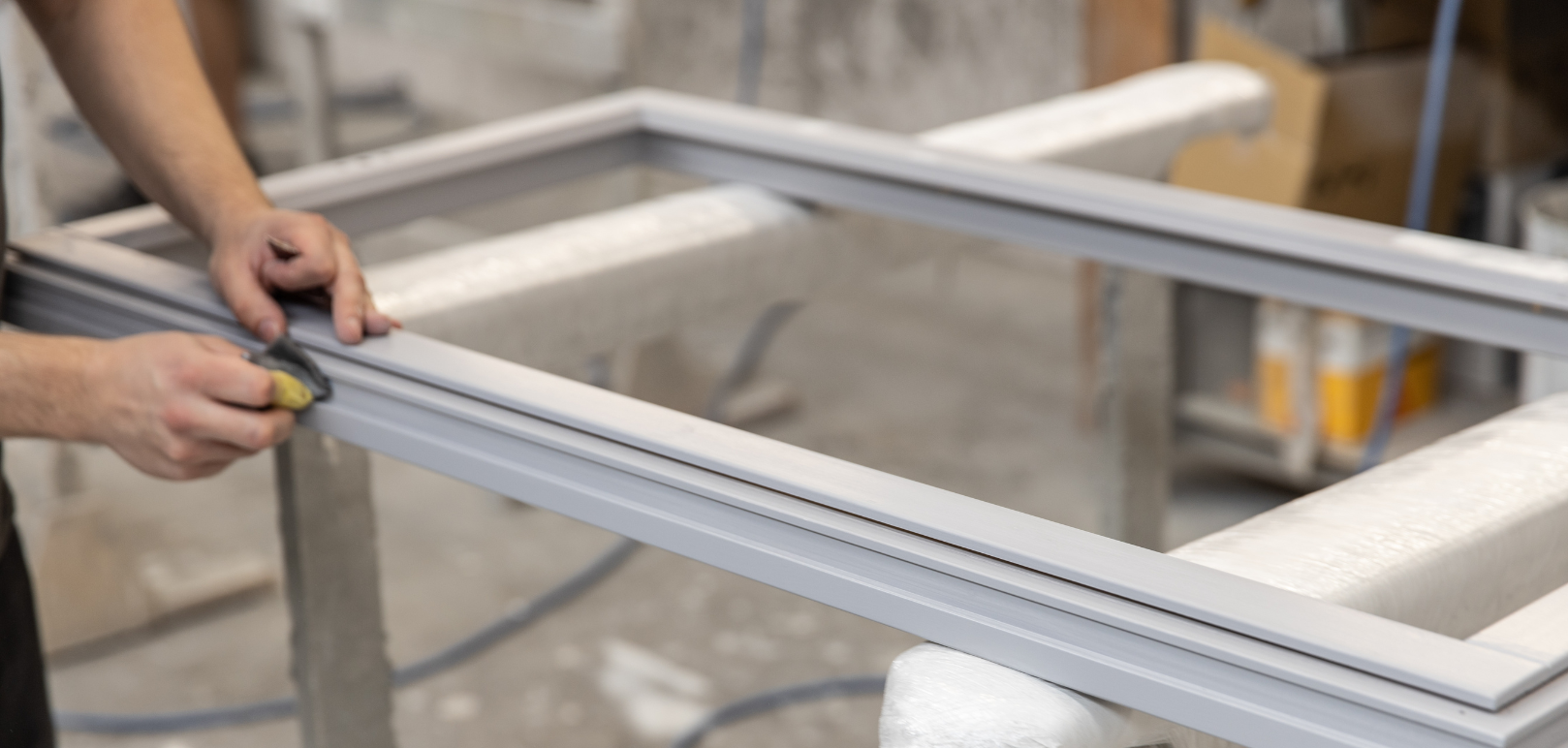

Glazing Process

Once the frames and trims are painted, they are ready to start the assembling process.

The installation of glass:

Energy-efficient double-pane insulated glass …

See Video

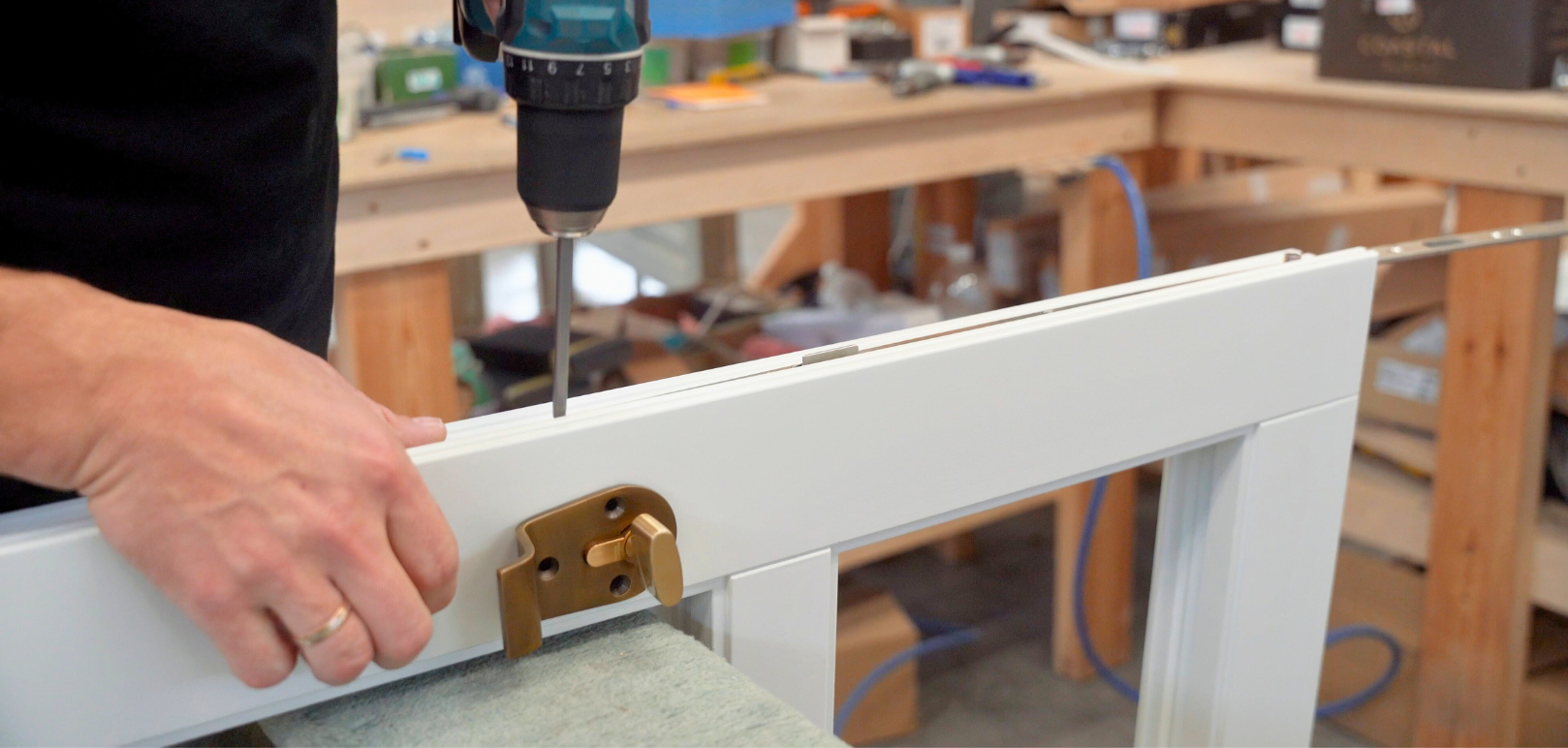

Window Assembly Part 1

The first stage of window assembly involves installing the hinges, locking mechanisms and gaskets, otherwise known as a window seal. The hinges we install are …

Learn More

Window Assembly Part 2

The second stage of window assembly involves the installation of handles. We offer a selection of high-quality handles from two renowned brands: Coastal and …

Learn More

Quality Control & Shipping

Once the timber windows and doors are completed, they undergo a rigorous quality control process, including thorough cleaning and inspection.

Upon arrival at …

See Video

Storage of Material

Storage of timber material is a combination of raw, pre-formed and laminated timber. The pre-formed timber consists of everything we need for our windows and …

Learn More

Cutting Aluminium Thresholds & Panels

Our cross-laminated timber is taken from storage, and our technicians begin by programming the chop saw machine to cut the desired length required for the door …

See Video

Planer Process for Doors

Once the timber is cut to the desired length, it enters the planing and sanding process, which serves two purposes. One is to remove rough edges or …

Learn More

UC11 Machine

The UC11 machine, otherwise known as a profiling machine, performs multiple tasks and is an important part of our window and door process. It profiles external …

See Video

Grooves (CNC Machine)

After the timber for windows and doors has been profiled, we use a CNC (Computer Numerical Control) machine specifically designed for precision cutting and …

See Video

Making the Frame for Doors

The timber pieces are then placed into a press machine, which is specifically designed for assembling and glueing door frames. The press applies pressure to the …

See Video

Adding Glazing Bars to Doors

Once the frames have been fully formed, integral external glazing bars, otherwise referred to as ‘astragal bars’, are profiled, glued and pinned to hold them in …

See Video

Priming & Caulking

Once the frames for window and door frames are pressed together, they are then prepped for the paint process. All of the internal and external joints are primed …

See Video

Priming Spray Shop

When the window and door frames reach the first stage of the spray shop, they are ready for full priming. The primer we use is a water-based, breathable system …

Learn More

Sanding Down Primer

Following the application of each primer coat, we meticulously sand the surface to achieve a smooth finish, eliminating any imperfections, rough patches, or …

Learn More

Top Coat Spray Shop

After priming and sanding, the window and door frames are sent to the spray shop, where they undergo a meticulous painting process, which involves three coats …

See Video

Glazing Process

Once the frames and trims are painted, they are ready to start the assembling process.

The installation of glass:

Energy-efficient double-pane insulated glass …

See Video

Door Assembly Part 1

In the initial phase of the door assembly, we focus on integrating essential components such as hinges, locking mechanisms, and gaskets, which are also referred …

See Video

Door Assembly Part 2

The second stage of door assembly involves the installation of handles. We offer a selection of high-quality handles from two renowned brands: Coastal and From …

Learn More

Quality Control & Shipping

Once the timber windows and doors are completed, they undergo a rigorous quality control process, including thorough cleaning and inspection.

Upon arrival at …

See Video

Storage of Material

Storage of timber material is a combination of raw, pre-formed and laminated timber. The pre-formed timber consists of everything we need for our windows and …

Learn More

Cutting To Desired Length

Our cross-laminated timber is taken from storage, and our technicians begin by programming the chop saw machine to cut the desired length required.

See Video

Cutting Aluminium Thresholds & Panels

Our cross-laminated timber is taken from storage, and our technicians begin by programming the chop saw machine to cut the desired length required for the door …

See Video

Planer Process for Windows

Once the timber is cut to the desired length, it enters the sanding process, which serves two purposes. One is to remove rough edges or imperfections, and the …

See Video

Planer Process for Doors

Once the timber is cut to the desired length, it enters the planing and sanding process, which serves two purposes. One is to remove rough edges or …

Learn More

UC11 Machine

The UC11 machine, otherwise known as a profiling machine, performs multiple tasks and is an important part of our window and door process. It profiles external …

See Video

Grooves (CNC Machine)

After the timber for windows and doors has been profiled, we use a CNC (Computer Numerical Control) machine specifically designed for precision cutting and …

See Video

Making The Frame for Windows

The timber pieces are placed into a press machine, which is specifically designed for assembling and glueing window frames and sashes. The press applies …

See Video

Making the Frame for Doors

The timber pieces are then placed into a press machine, which is specifically designed for assembling and glueing door frames. The press applies pressure to the …

See Video

Glazing Bars to Window Sashes

Once the timber sashes have been fully formed, integral external glazing bars, otherwise referred to as ‘astragal bars’, are profiled, glued and pinned to hold …

Learn More

Adding Glazing Bars to Doors

Once the frames have been fully formed, integral external glazing bars, otherwise referred to as ‘astragal bars’, are profiled, glued and pinned to hold them in …

See Video

Priming & Caulking

Once the frames for window and door frames are pressed together, they are then prepped for the paint process. All of the internal and external joints are primed …

See Video

Priming Spray Shop

When the window and door frames reach the first stage of the spray shop, they are ready for full priming. The primer we use is a water-based, breathable system …

Learn More

Sanding Down Primer

Following the application of each primer coat, we meticulously sand the surface to achieve a smooth finish, eliminating any imperfections, rough patches, or …

Learn More

Top Coat Spray Shop

After priming and sanding, the window and door frames are sent to the spray shop, where they undergo a meticulous painting process, which involves three coats …

See Video

Glazing Process

Once the frames and trims are painted, they are ready to start the assembling process.

The installation of glass:

Energy-efficient double-pane insulated glass …

See Video

Window Assembly Part 1

The first stage of window assembly involves installing the hinges, locking mechanisms and gaskets, otherwise known as a window seal. The hinges we install are …

Learn More

Door Assembly Part 1

In the initial phase of the door assembly, we focus on integrating essential components such as hinges, locking mechanisms, and gaskets, which are also referred …

See Video

Window Assembly Part 2

The second stage of window assembly involves the installation of handles. We offer a selection of high-quality handles from two renowned brands: Coastal and …

Learn More

Door Assembly Part 2

The second stage of door assembly involves the installation of handles. We offer a selection of high-quality handles from two renowned brands: Coastal and From …

Learn More

Quality Control & Shipping

Once the timber windows and doors are completed, they undergo a rigorous quality control process, including thorough cleaning and inspection.

Upon arrival at …

See Video